Cannabis Growers Consider Broader Options to Improve Facility Water Efficiency

U.S. Legal Cannabis Water Use to Almost Double by 2025

February 24, 2021

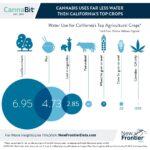

Legal Cannabis Cultivation’s Footprint Sinks Common Assumptions About Comparative Water Use

March 8, 2021By John Kagia, Chief Knowledge Officer, New Frontier Data

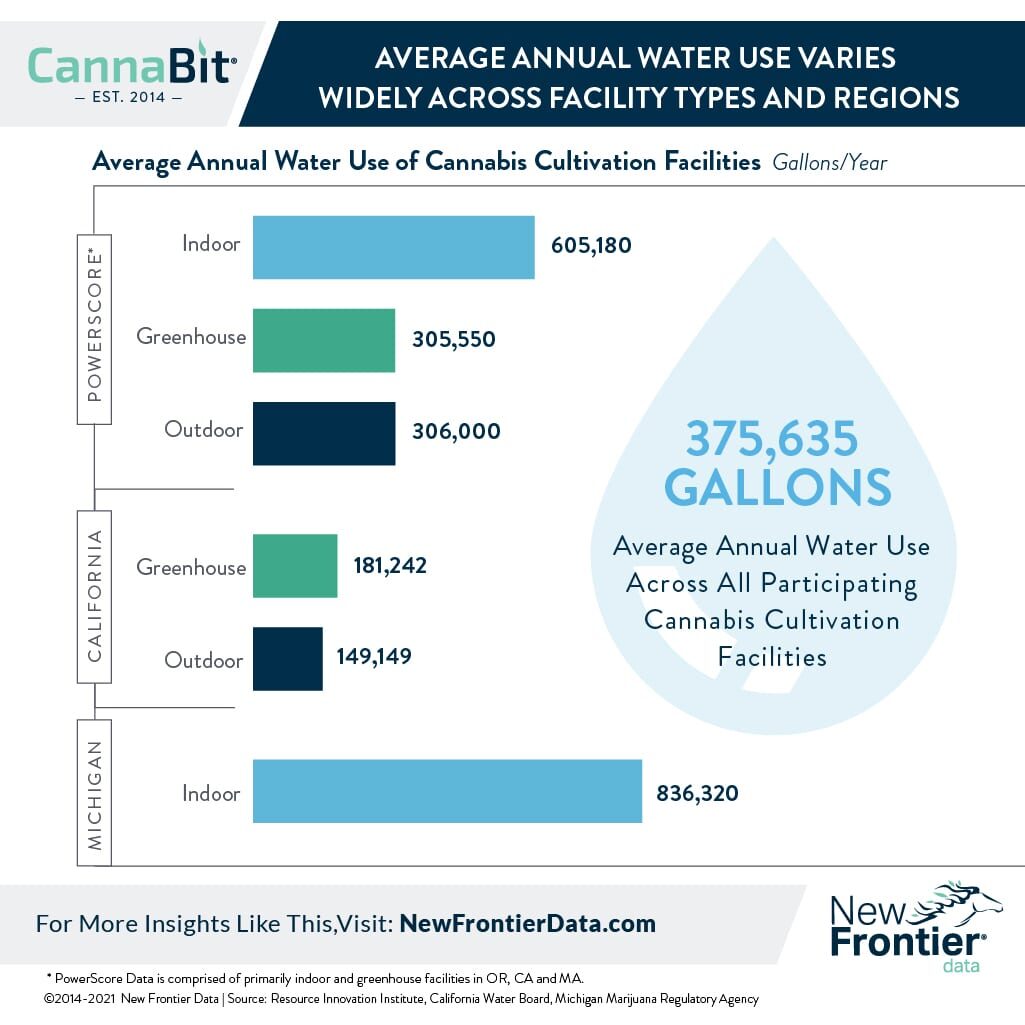

Annual water usage for cannabis cultivation varies widely, depending on the type and scale of a given facility. Data from markets across the country show that indoor facilities use significantly more water per year than do greenhouse or outdoor facilities. However, the comparative usage rates do not necessarily indicate that indoor facilities are more inefficient in using their water than are those operating greenhouses or outdoor grows.

The widely varied cultivation practices across respective facility types make it challenging to normalize water-use practices or totals across different facilities and locales based simply on annual volumes of water used. Unsurprisingly, the biggest single driver of water use is the number of harvests which any facility produces in a year. Generally speaking, outdoor facilities have one harvest per year, whereas greenhouse facilities yield two or three harvests, and indoor facilities can produce five or more harvests per year. Since water use is directly correlated to the number of plants cultivated, facilities with more frequent harvests will expectedly use more water than those harvesting but once or twice annually. Consequently, the frequency of harvests is a fundamental reason why indoor facilities generally report annually using 4x to 5x the amount of water used by outdoor facilities.

Therefore, measuring water use per gram produced proves to be a more telling metric to effectively compare the relative performances of different facility types, as that measure accounts for actual crop yields, and not merely the total water used by cultivators throughout the year. That and other comparative metrics are explored in a new report this month, Cannabis H20: Water Use and Sustainability in Cultivation, New Frontier Data’s latest comprehensive analysis of how water is most efficiently and sustainably used for growing cannabis.

Opportunities exist to reduce water consumption across all facilities types. The technological shift from hand-watering with pipes to drip irrigation has played a major role in lowering water use in the legal market relative to unrelated markets (where managing water use is rarely a prioritized consideration), and innovation is likewise further advancing water-use efficiency across the legal industry. An increasing availability of sensor-based watering solutions — which provide real-time measurement of moisture content and electrical conductivity in the substrate, and apply micro-pulses of water to ensure optimal moisture levels — are but one example of emerging technologies which can decrease the volume of water consumed for irrigation by up to 90% (depending on a facility’s previous irrigation techniques).

Other factors contribute to determining how much water a facility will use. Facilities which reclaim and recycle water in their processes respectively require far less water than do those relying solely on fresh water supplies. Water reclamation can take several forms, but two approaches representing the greatest impacts on water use are runoff reclamation and condensate capture. Reclaiming runoff involves collecting excess water not absorbed by either the plant or substrate during irrigation, and processing it for reuse. Depending on a given irrigation technique, some 25% or more of applied water can end up going down the drain, underscoring reclamation’s important capability toward reducing waste. That said, risks may exist in reclaiming runoff (e.g., most critically, water that is not properly treated can spread diseases from a few localized plants to an entire crop). Additionally, reclaimed runoff must be tested to determine how the nutrient balance may have shifted during irrigation, and rebalanced to ensure that plants receive the appropriate nutrient profile.

Historically, concerns about contamination and nutrient imbalance have raised barriers to incorporation of reclamation in cannabis cultivation. However, as water capture and treatment solutions have become more widely available and efficient, growers enjoy an expanding range of options for safely reusing their runoff.

Condensate capture is another approach that can yield high returns for indoor and enclosed greenhouse facilities. Since more than 90% of the water typically absorbed by cannabis plants is used to cool their leaves through evapotranspiration, much of that water can be reclaimed through HVAC condensate. Yet because condensate may become tainted by heavy metals due to leaching within the HVAC system, that captured water must be regularly tested to ensure proper filtration before the water is reapplied to any plants. Due to the significant volumes of water that can be collected as condensate, water storage capacity may also present a challenge for space-constrained facilities. However, with sufficient pre-planning in facility design, sustainable reuse of condensate may be a highly impactful means to lower a facility’s water footprint.

Taken together, responsible and efficient approaches can dramatically lower an operation’s overall water use. Furthermore, with many of the world’s leading cannabis-producing regions facing increasing risks of acute drought conditions due to climate change, not only will efficient water use improve cultivators’ bottom lines, but strengthen their respective competitive positions, and improve the overall environmental sustainability of the industry for growers everywhere.