Capturing the Energy Costs for Cannabis Cultivation

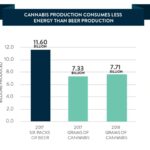

Cannabis Production Consumes Less Energy Than Beer Production

September 30, 2018

DEA’s Rescheduling of CBD Is No Industry Cure-All

October 7, 2018Capturing the Energy Costs for Cannabis Cultivation

By J.J. McCoy and Beau Whitney for New Frontier Data

Cannabis industry stakeholders, much like other stakeholders operating in agricultural and livestock commodities, place a great deal of emphasis on energy consumption and carbon-emissions levels. Whether framed by cultivators and producers as economic fixed costs, ongoing governmental policy, or the industry’s environmental legacy, the continuing challenges and consequences of large-scale harvesting are matters of perennial urgency.

In the forthcoming Cannabis Energy Report, New Frontier Data has joined both Scale MicroGrid Solutions and the Resource Innovation Institute to provide a landmark, comprehensive study about the challenges of energy consumption and carbon emissions throughout the cultivation and production cycles of cannabis. Until now, many industry stakeholders have been relying on data and analysis based on research collected prior to the deployment of legalized medical and adult-use programs throughout 31 states and the District of Columbia.

While the cannabis industry at large is not a major consumer of energy relative to high-user industries such as the automotive, steel, or medical-care industries, its energy use is significant, and important to its consumers. Legal cannabis cultivation in the U.S. consumes slightly more energy than that of all the Starbucks locations in the nation, but less than what it would take to run every electric car in the country, and an approximately equivalent amount to run 92,500 households for a year. Given that energy consumption is expected to increase 162% from 2017 to 2022, understanding consumption data becomes a vital bit of operational intelligence.

For example, the City of Denver was on the verge of missing its targeted goals for energy reduction when they discovered the lack of data about energy consumption within the cannabis industry. City leaders were surprised last spring when Denver’s Department of Public Health and Environment reported that the cannabis industry accounted for 3.9% of the city’s energy usage in 2016. This amount was approximately double that required by the industry in 2014, when the country’s first legal adult-use sales began in Colorado.

To help provide companies with detailed analysis to determine exactly how energy is used in a given facility, the Resource Innovation Institute devised its Cannabis PowerScore tool and website. Using these tools, growers privately input their operational data and cultivation characteristics to inform detailed, aggregated reports on efficiencies and trouble zones in comparison to other operations. As the largest, cannabis-specific, energy-use dataset currently available, PowerScore has been an invaluable tool and is expected to become increasingly integral as the growing industry matures.

By tracking energy usage and costs, a business can assess its standing relative to others in the marketplace and dataset. The tool establishes and tracks indicators – such as grams per kilowatt hour (KwH), KwH per square foot, pounds of carbon per gram, output per square foot, and energy cost per gram – to gather a solid baseline, identifying where a company’s costs are, and where opportunities reside to reduce them, according to annual production, annual electricity consumption, canopy area, cultivation type, and lighting type, etc.

In general, indoor and greenhouse cultivation use more energy than outdoor grows. However, given the fixed costs in cannabis production, the ability to identify and reduce electrical use can offer considerable competitive advantages.